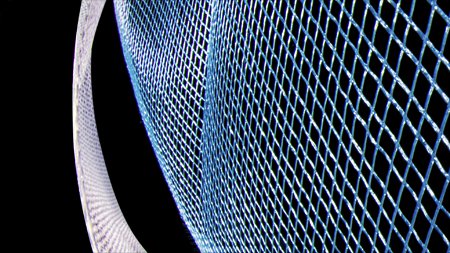

Laid scrims

Open Scrims

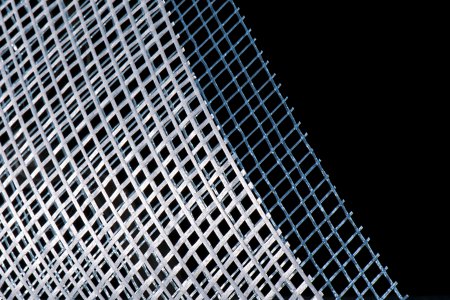

Open scrims or meshes are often the most effective and economic solution for flexible reinforcements. Due to the open construction and the chemical additives, the scrims allow to be fully incorporated in almost any material. A laid scrim looks like a grid where the yarns are laid rectangular and bonded by a chemical to hold the structure and stability of the scrim . We produce the scrims out of multifilament polyester or glass yarns mainly for the use as a reinforcement scrim in different applications.

Characteristics

The difference with a woven scrim is that a woven scrim has both a mechanical and chemical bonding where the laid scrim is a flat structure grid with only a chemical bonding. The fact that the upper and lower warp in laid scrims will always be on the same side of the weft yarns guarantees that the warp yarns will always be under tension. In this way tensile forces in the warp direction will be absorbed immediately. Thanks to this effect, laid scrims often exhibit a strongly reduced elongation.

Whilst woven products may be supplied loomstate, a laid scrim will always be impregnated. Sioen has an extensive knowledge in respect to which binder may be best suited to different applications. The choice of the right adhesive may enhance the bonding of the laid scrim with the final product considerably.

Applications

The mechanical values of bitumen roof sheets are substantially improved by the use of scrims.

Materials that tend to tear easily, such as paper, foil or films from different plastics, will be effectively tear-proofed by laminating with laid scrims. When laminating a scrim between two layers of film or other materials, less adhesive will be needed and the cohesion of the laminate will be improved.

Scrim production always involves a thermal drying. This pre-shrinks the polyester and other thermoplastic yarn, thereby substantially improving subsequent treatments by the customer.