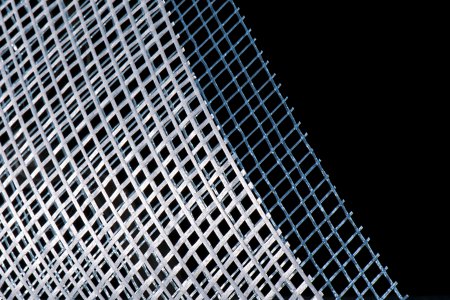

Laid scrims

Characteristics

The difference with a woven scrim is the fact that a woven scrim has a mechanical and chemical bonding where the laid scrim is a flat structure grid with only a chemical bonding. The fact that the upper and lower warp in laid scrims will always be on the same side of the weft yarns guarantees that the warp yarns will always be under tension. Therefore tensile powers in warp direction will be absorbed immediately. Due to this effect, laid scrims often show a strongly reduced elongation.

Whilst woven products may be supplied loomstate, a laid scrim will always be impregnated. Sioen has an extensive knowledge in respect to which binder may be best suited to different applications. The choice of the right adhesive may enhance the bonding of the laid scrim with the final product considerably.

Applications

The mechanical values of bitumen roof sheets are substantially improved by the use of scrims.

Materials that tend to tear easily, such as paper, foil or films from different plastics, will be prevented from tearing effectively by laminating these with laid scrims. When laminating a scrim between two layers of film or other materials, less adhesive will be needed and the cohesion of the laminate will be improved.

The production of scrims always requires a thermal drying process. This leads to preshrinking of the polyester and other thermoplastic yarns which will improve substantially subsequent treatments done by the customer.